Vatva, Ahmedabad, Gujarat

- GST NO. : 24AXZPR1084P1ZF

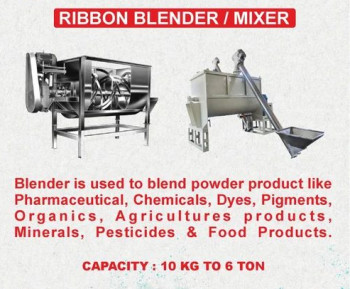

Ribbon Blender

Leading Manufacturers and Wholesaler of Mild Steel Conical Ribbon Blender and Mild Steel Ribbon Blender from Ahmedabad.

| Business Type | Manufacturer, Supplier |

| Capacity | 50 Kg |

| Material | Mild Steel |

| Power | 50 KW |

| Country of Origin | India |

| Frequency | 50 Hz |

| Voltage | 415 V |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Finishing | Polished |

| Usage / Application | Industrial |

Preferred Buyer From

| Location | Anywhere in India |

A vertical ribbon mixer is a type of industrial mixing equipment designed for blending powders, granules, and other bulk materials in a vertical orientation. This mixer is particularly effective for achieving homogeneous mixtures in applications where space is limited or where vertical integration is advantageous. Here’s a detailed overview of its design, features, benefits, and applications:How It Works:Design: The vertical ribbon mixer consists of a vertical cylindrical chamber with a ribbon agitator inside. The ribbon agitator typically has two helical ribbons that rotate around a central shaft, moving material upward and downward within the chamber.

| Business Type | Manufacturer, Supplier |

| Capacity | 200 Liters |

| Mixer Type | Ribbon |

| Country of Origin | India |

| Frequency | 50 Hz |

| Application | Industrial |

| Automatic Grade | Automatic |

| Driven Type | Electric |

| Material | Stainless Steel |

| Phase | 3 Phase |

Preferred Buyer From

| Location | Anywhere in India |

A ribbon blender mixer is a type of industrial mixing equipment used to blend powders, granules, and other bulk materials. It's known for its efficiency in achieving a uniform mix in a short period. Here's a breakdown of how it works and its key features:

How It Works:

Design: The blender consists of a horizontal, cylindrical shell with a ribbon-like agitator mounted inside. The ribbon agitator has two helical ribbons that rotate in opposite directions.

Mixing Action: As the ribbons rotate, they move materials from the center to the outer edges and back again, creating a continuous flow that ensures thorough mixing. This action helps achieve a homogenous mixture with minimal segregation.